- This topic is empty.

-

AuthorPosts

-

2025-12-29 at 9:17 am #12815

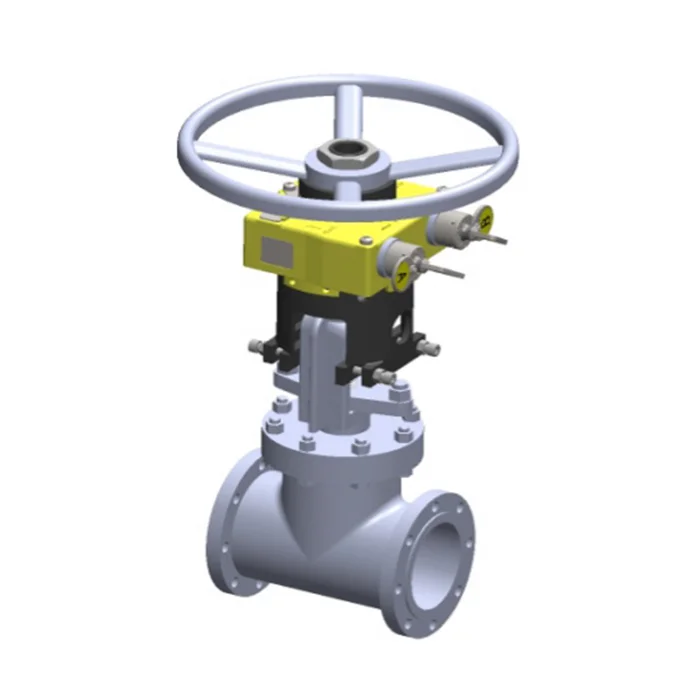

High-pressure systems are essential components in various industrial applications, including oil and gas pipelines, chemical processing plants, power generation, and water treatment facilities. These systems operate under extreme pressures, and even minor errors in valve operation can result in catastrophic consequences, including equipment damage, process disruption, or severe safety hazards. Mechanical valve interlock devices are critical for ensuring the safe and efficient operation of high-pressure systems, providing a fail-safe mechanism to enforce correct valve sequencing and prevent human errors.

This article explores the role, types, design considerations, and best practices for using mechanical valve interlock devices in high-pressure systems.

Understanding Mechanical Valve Interlock Devices

Mechanical valve interlock devices are engineered systems designed to physically control the sequence of valve operations. Unlike electronic interlocks, which rely on sensors and control logic, mechanical interlocks use physical mechanisms such as keys, cams, levers, and locking pins to enforce operational safety. Their simplicity and reliability make them particularly suitable for high-pressure systems where failure is not an option.

The primary objectives of mechanical valve interlock devices in high-pressure systems include:

Ensuring safe sequencing of valves to prevent overpressure, backflow, or fluid surges.

Reducing human error during startup, shutdown, or maintenance.

Protecting personnel and equipment from potentially hazardous high-pressure fluids.

Complying with safety regulations such as OSHA, API, and other industry standards.

Challenges in High-Pressure Systems

Operating valves in high-pressure systems presents unique challenges:

Risk of Overpressure: Incorrect valve sequencing can cause sudden pressure surges, potentially damaging equipment or pipelines.

Safety Hazards: High-pressure fluids, including gases and liquids, can pose life-threatening risks if valves are opened or closed incorrectly.

Complex Valve Networks: High-pressure systems often include multiple valves, each affecting the flow and pressure of other parts of the system.

Maintenance Difficulties: Access to high-pressure valves is often limited, requiring devices that are reliable, durable, and easy to operate.

Mechanical valve interlock devices address these challenges by ensuring that valves are operated in a precise, controlled sequence.

Types of Mechanical Valve Interlock Devices for High-Pressure Systems

Mechanical valve interlocks can be adapted to high-pressure applications through specialized designs. The most common types include:

1. Key Interlock Systems

Key interlock systems are widely used in high-pressure applications. Each valve is equipped with a lock that can hold or release a key only when the valve is in a specific position, ensuring a strict operational sequence.

Features for High-Pressure Applications:

High-strength keys and locks designed to withstand mechanical stress.

Custom sequences tailored to high-pressure system layouts.

Ability to integrate with multiple valves for complex operations.

Benefits:

Prevents simultaneous operation of conflicting valves.

Reduces the risk of pressure surges or backflow.

Highly reliable and fail-safe.

2. Cam-Operated Interlocks

Cam-operated interlocks use rotating cams or levers to control the movement of locking pins or other mechanisms. The cam profile ensures that a valve can only operate when adjacent valves are in correct positions.

Features for High-Pressure Applications:

Heavy-duty cams constructed from high-strength steel or alloy.

Precision design to handle high torque during valve operation.

Ability to manage complex valve sequences.

Benefits:

Precise control in multi-valve high-pressure systems.

Durable under high torque and mechanical stress.

Adaptable to existing valve layouts.

3. Lockout/Tagout (LOTO) Interlocks

LOTO interlocks integrate mechanical locking with safety tags and padlocks to ensure compliance during maintenance or emergencies.

Features for High-Pressure Applications:

Reinforced locking mechanisms to prevent accidental release under pressure.

Multiple padlock slots for multi-operator safety.

Highly visible tags indicating valve status.

Benefits:

Protects maintenance personnel from high-pressure hazards.

Ensures compliance with safety regulations.

Allows secure isolation of high-pressure sections during servicing.

4. Customized Multi-Valve Interlocks

High-pressure systems often include networks of interconnected valves, requiring customized interlocks to enforce correct sequencing across multiple points.

Features:

Modular designs for easy expansion or reconfiguration.

Heavy-duty construction to handle extreme pressures and forces.

Integration with both key and cam-operated mechanisms.

Benefits:

Comprehensive safety for complex high-pressure systems.

Reduces risk of operational errors across multiple valves.

Flexible for system upgrades or modifications.

Design Considerations for High-Pressure Systems

When selecting and installing mechanical valve interlock devices for high-pressure applications, several design considerations are critical:

Material Strength: Components must withstand high mechanical stress and extreme pressures. Stainless steel, hardened alloys, or reinforced composites are often used.

Valve Compatibility: The interlock must fit the specific valve type, size, and operating torque.

Environmental Resistance: High-pressure systems may operate under high temperatures, corrosive fluids, or vibration. Devices must resist these conditions.

Accessibility: Ensure operators and maintenance personnel can safely access interlocks for operation and inspection.

Sequence Complexity: High-pressure systems often require precise multi-valve sequencing; interlocks must accommodate these requirements.

Redundancy and Fail-Safe Design: Mechanical interlocks should default to a safe position in the event of failure, preventing dangerous operations.

Installation Best Practices

Proper installation is critical for ensuring the effectiveness of mechanical valve interlocks in high-pressure systems. Common best practices include:

Follow Manufacturer Guidelines: Always adhere to installation instructions specific to high-pressure applications.

Verify Alignment: Ensure precise alignment of keys, cams, and locking pins to handle high torque.

Test Sequences Thoroughly: Simulate real operating conditions to confirm proper interlock function before commissioning.

Train Operators: Provide comprehensive training on proper operation, emergency procedures, and maintenance.

Document Procedures: Maintain clear documentation of valve sequences, interlock design, and operational protocols.

Maintenance Considerations

Mechanical valve interlock devices for high-pressure systems require regular inspection and maintenance to ensure reliability:

Lubrication: Use high-quality lubricants suitable for high-pressure environments to maintain smooth operation.

Wear and Tear Monitoring: Inspect keys, cams, and locking pins for signs of wear or deformation.

Environmental Checks: Verify resistance to corrosion, temperature extremes, and vibration.

Functional Testing: Conduct periodic tests to ensure interlocks are enforcing correct sequences.

Routine maintenance reduces the risk of failure and extends the service life of both the interlock and the associated valves.

Advantages of Mechanical Valve Interlocks in High-Pressure Systems

Mechanical valve interlocks provide several advantages in high-pressure applications:

Fail-Safe Operation: Mechanical design ensures reliability even in power outages or electronic failures.

Accident Prevention: Enforces correct sequencing, reducing the risk of pressure surges or hazardous releases.

Durability: High-strength materials withstand extreme pressures, temperature, and mechanical stress.

Regulatory Compliance: Supports adherence to industry safety standards.

Cost-Effective: Lower maintenance and operational costs compared to complex electronic control systems.

Future Trends

The future of mechanical valve interlocks in high-pressure systems includes:

Integration with Smart Sensors: Monitoring valve positions and operational sequences in real-time.

IoT Connectivity: Enabling predictive maintenance and data analytics for system safety.

Advanced Materials: Development of ultra-durable, corrosion-resistant, and lightweight components.

Customizable Modular Designs: Adaptable solutions for evolving high-pressure systems.

Enhanced Safety Features: Ergonomic operation, visual indicators, and fail-safe enhancements.

These innovations will maintain the reliability of mechanical interlocks while enhancing operational efficiency, monitoring capabilities, and safety in high-pressure systems.

Conclusion

Mechanical valve interlock devices are indispensable for high-pressure systems, providing a fail-safe solution to prevent operational errors, protect equipment, and ensure personnel safety. From key interlocks to cam-operated and customized multi-valve systems, these devices are designed to withstand the extreme demands of high-pressure applications. Proper selection, installation, and maintenance are crucial to achieving maximum safety and operational efficiency.

As technology evolves, mechanical valve interlocks are likely to integrate with digital monitoring systems, IoT connectivity, and predictive maintenance tools, enhancing their functionality while retaining their core mechanical reliability. For industries operating under high pressure, investing in high-quality mechanical valve interlock devices is not just a safety measure—it is a strategic decision that safeguards personnel, protects critical equipment, and ensures long-term operational success.

http://www.nudango.com

nudango -

AuthorPosts

- You must be logged in to reply to this topic.