- This topic is empty.

-

AuthorPosts

-

2025-07-09 at 5:56 pm #11626

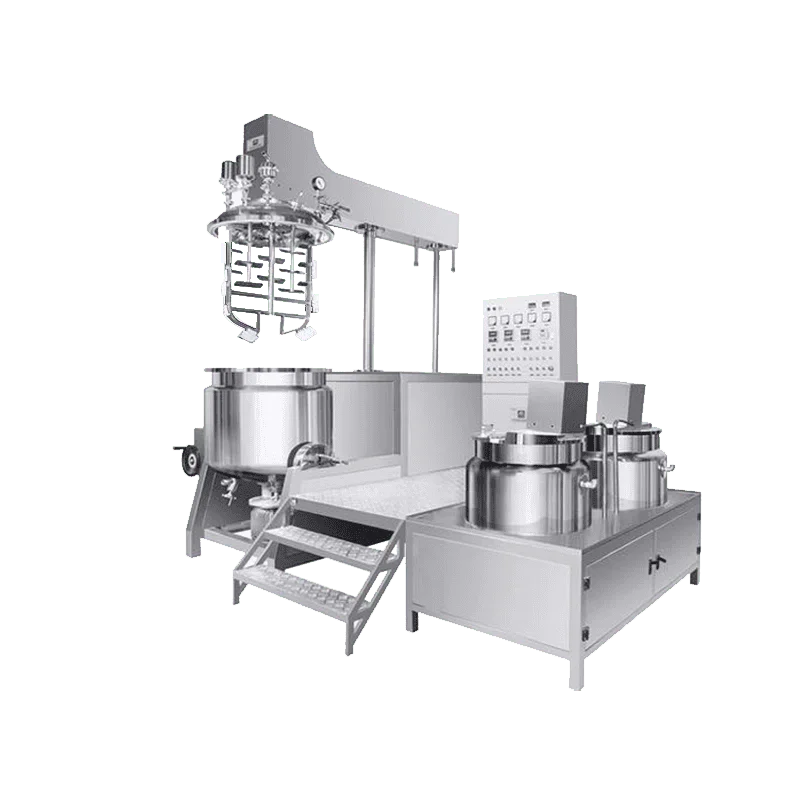

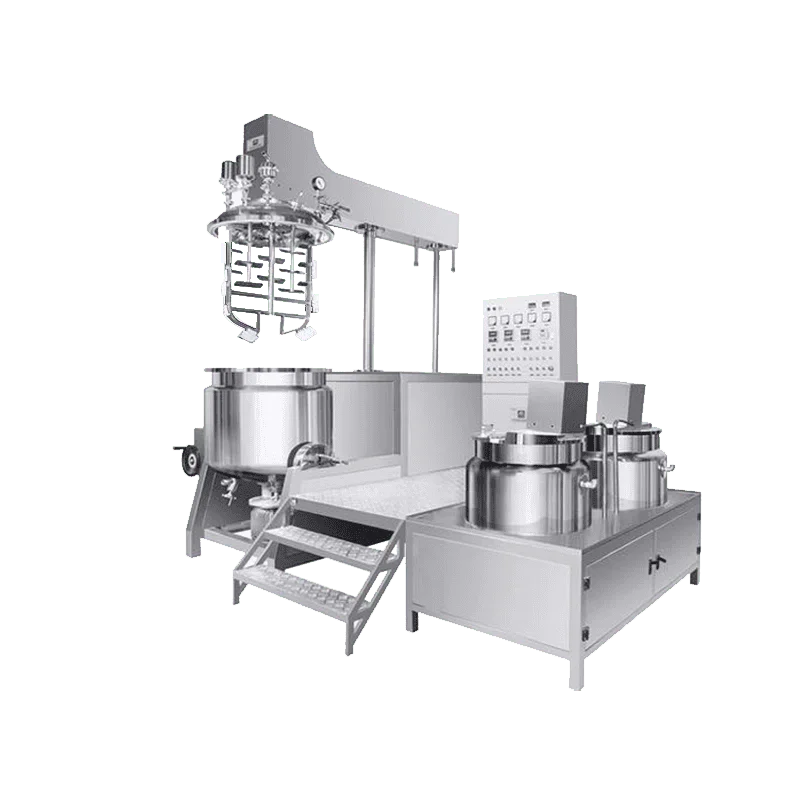

In industries such as cosmetics, pharmaceuticals, food processing, and chemicals, the quality of emulsification and homogenization processes directly affects the final product’s performance, stability, and appearance. One of the most efficient tools used to achieve high-quality mixing results is the Bottom Vacuum Emulsifier Homogenizer Mixer.

In this article, we’ll explore what this equipment is, how it works, its core advantages, and why companies like Orisun, a professional mechanical design and manufacturing enterprise, are at the forefront of delivering customized, high-performance solutions.

Understanding the Bottom Vacuum Emulsifier Homogenizer Mixer

A Bottom Vacuum Emulsifier Homogenizer Mixer is a type of industrial mixing equipment designed to produce uniform, stable emulsions and dispersions under vacuum conditions. Unlike traditional mixers that rely on top-mounted motors and agitators, this machine operates from the bottom of the mixing tank, offering a more compact, efficient, and powerful method of processing.

It combines three key processes into one integrated system:

Emulsifying – Mixing immiscible substances like oil and water into a stable emulsion.

Homogenizing – Reducing particle sizes and ensuring consistency throughout the product.

Vacuum Mixing – Removing air bubbles and preventing oxidation during the mixing process.

How Does It Work?

The bottom-mounted high-shear homogenizer creates a strong vortex that draws materials downward, forcing them through a high-speed rotor-stator system. Under vacuum, the mixer simultaneously deaerates the batch, improving product stability and texture. The result is a smooth, finely dispersed mixture that meets high industrial standards.

The vacuum environment also minimizes contamination, making it ideal for sterile or sensitive formulations, such as pharmaceutical creams, cosmetic lotions, and food sauces.

Key Advantages of Bottom Vacuum Emulsifier Homogenizer Mixers

1. Efficient Particle Reduction

By using high shear force and continuous recirculation, the mixer ensures that particles are broken down uniformly, leading to finer emulsions and more consistent results.

2. Vacuum Deaeration

Removing trapped air helps prevent foaming, improves product density, and enhances shelf life—especially crucial in cosmetic and pharmaceutical applications.

3. Energy and Time Savings

The bottom-driven design offers faster mixing with lower energy consumption. Because mixing and homogenizing occur simultaneously, overall production time is significantly reduced.

4. Sanitary Design

Made from stainless steel and engineered for clean-in-place (CIP) processes, this mixer meets strict hygiene standards and is suitable for food-grade and medical applications.

5. Compact System Integration

Compared to top-mounted mixers, the bottom vacuum design allows for a more compact structure, reducing the machine's overall footprint and simplifying maintenance.

Why Choose Orisun?

Orisun is an enterprise deeply involved in the design and manufacturing of advanced mechanical systems, including emulsifying and homogenizing equipment. With a focus on innovation, customization, and quality, Orisun provides industrial mixing solutions tailored to your unique production requirements.

Whether you're scaling up production or developing sensitive formulations, Orisun engineers will work with you to configure a Bottom Vacuum Emulsifier Homogenizer Mixer that optimizes your processes, improves efficiency, and ensures consistent output quality.

Applications Across Industries

Cosmetics: Creams, lotions, serums, and sunscreens

Pharmaceuticals: Ointments, gels, emulsions, and suspensions

Food Processing: Sauces, dressings, dairy emulsions

Chemicals: Paints, a

http://www.orisunmachinery.com

Orisun -

AuthorPosts

- You must be logged in to reply to this topic.